Troubleshooting is the most overlooked aspect of powder coating

Going over what your getting is important as much as what to go over when working with a powder coater. The most overlooked aspect of powder coating is knowing the level of restoration you’re going to get for that perfect powder coat finish.

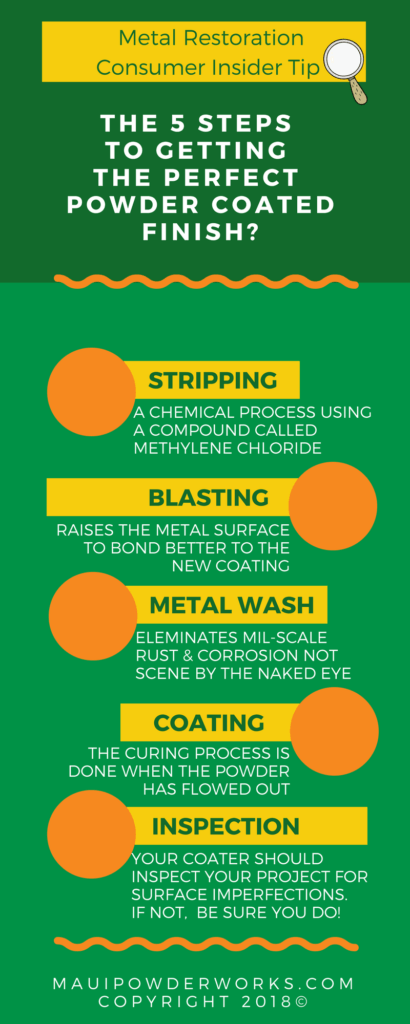

When going to your local coater be sure to ask how they go about restoring your project. Most quality custom coaters use a 5-stage restoration process to make sure your project gets done right. When you’re working on your prized or sentimental project it’s important to know that you’re getting it done right so be sure ask so you know what you’re getting into because restoration can be expensive and time-consuming.

1. Stripping is a chemical process using a compound called methylene chloride which activates the paint to bubble up and pull away from the surface to be removed with an abrasive tool like steel brush, steel wool or paint scraper.

2. Blasting through a pressure pot at a high psi(air pressure) and is next to help remove the excess paint left over from stripping and raise the metal surface to bond better to the new coating. There are few different kinds of media available which when combined with pressurized air become the ideal dry prep

3. Metal Prep Wash should be used especially when older metal or grimy parts are being done. There are (alkaline) salt remover solutions and acid-based solutions depending on the type of metal being powder coated. They help in removing extra fine debris and mil-scale rust or corrosion not seen by the naked eye.

4. Powder Coat & Curing is by where the metal is electrically charged to attract the powder particles then baked at temperatures not exceeding 500 degrees with specific time limits. When the powder is cured it means that the powder has bonded together(flowed out) and fully harden when the metal cools

5. Inspection is the very last step to ensure that the finish is lacking cross-contamination and other surface issues like outgassing, peeling, and fish-eye which can be common issues in restoration. Be sure to go over your project with you powder coater at the time of pick up.

A final note: To help customers search for quality coatings there are powder coater member groups which custom coaters can be affiliated. One of them is called the Powder Coating Institute (PCI). A hallmark of PCI is their Powder Coated Tough Mark. It is used by coaters and manufacturers to make consumers aware that their products are finished with this environmentally friendly process.

For a simple directory, search nationally by going to Powder Coating Near Me. Those needing powder coating services can search this directory for coaters in their area who are committed to providing a certain types of specialty.

About us

RossKote is committed to sharing their experience in metal coatings, painting, and restoration so customers & powder coaters can navigate the process of powder coating and make the best choices for getting their projects done.

RossKote regularly contributes helpful videos on his blog and YouTube channel.

Join us. As we build a powder coating community online to share our passion for performance finishes by subscribing to RossKote's Powder Coater Podcast

Connect with us. Comment below. What would you like to know more about? I love to answer everyday questions to the consumer market wants to know about powder coating.

MAUIPOWDERWORKS.COM

Copyright 2016-2022©