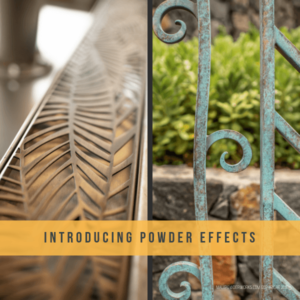

Patina Powder Coat

A new line of powder coated effects

Learn more from our sister sites

PatinaPowderCoat.com

Whether you’re an industry peep or love to learn about new finishes be sure you stay tuned to receive the latest info on our line of Powder Effects©. Learn more

CoaterFX.com

Scaling your coating skills can be just as valuable as upgrading equipment. Aren’t you worth it? Join an elite group of applicators able to offer this finish. Learn more

We call it aging without the waiting

Our new line of distressed powder coated finishes called Patina Powder Coat is going to change the way you think about metal applications. The innovative applications can produce beautiful, realistic finishes that are in demand without losing their toughness and durability the industry has come to expect.

get it here exclusively

As the only state certified applicator we will give you the custom distressed effect finish your project deserves. Our effects have all the super durability needed against our extreme Hawaii climate.

Variation abounds

These luxury looks fool the keenest eye without the hefty price tag of using expensive copper or harsh chemicals. Our line of styles and variations are only limited by your imagination. What’s your vision?

about the inventor

Owner Ross Scott was inpired to acheive powder coating effects as a creative force in the production of patina coating on metal. His aged patina finishes ignite a new genre of looks for the luxury home, residential or resort markets.

Get a quote

808-667-9690

PayPal, Visa & MC accepted

Get our sample book!

Get all the project images from our gallery & more! Get a download link to view plus an opportunity to order a hardcopy or live sample. Over 60 pages of projects & information.

Read our featured article

Read our four page featured article in Powder Coated Tough magazine where we explore & unpack about these finishes.