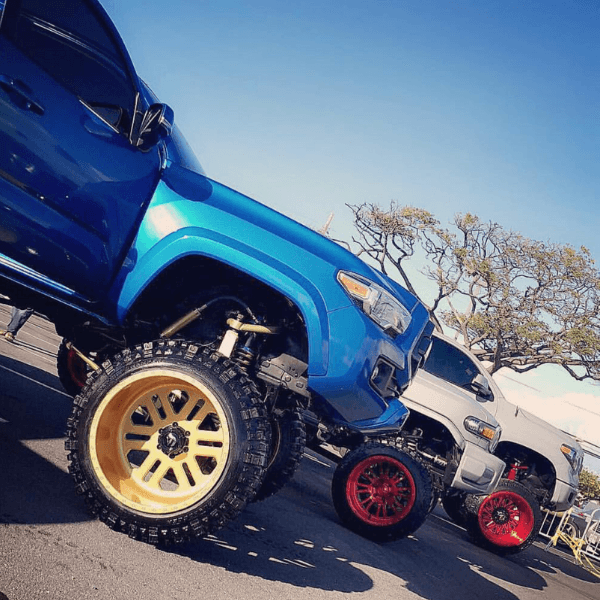

RIMS WE'VE DONE

Powder Coat Rims

Get ready like a pro

Customizing your wheels for a car, truck or motorcycle? We are the best source for tips and tricks to powder coated rims. Whether you have new, used or aftermarket rims we’re the guys that will give you what you need to know on alloy, steel, and aluminum rims.

No matter where you are or who you choose in Hawaii for powder coating, we’ll get you ready like a pro.

Step 1. Sign Up

STEP 2. IMAGINE THE POSSIBILITIES

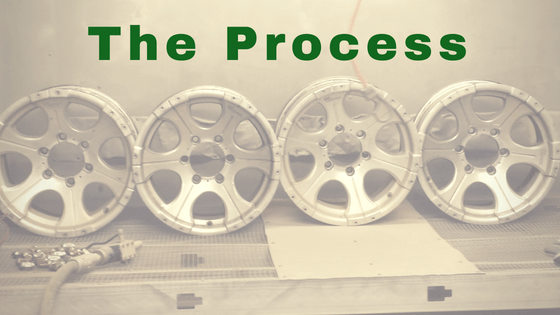

It’s all included. Think change needs to be expensive? It doesn’t…Check out these rims we did for just $500. Includes stripping, sandblasting, powder, and coating with one of our IN-STOCK COLORS

Tire service availability

Most customers drop off and handle dismounting their rims on their own. However, we do use local tire service suppliers that provide dismount and balance services. We will provide free pick up and delivery with our rim service.

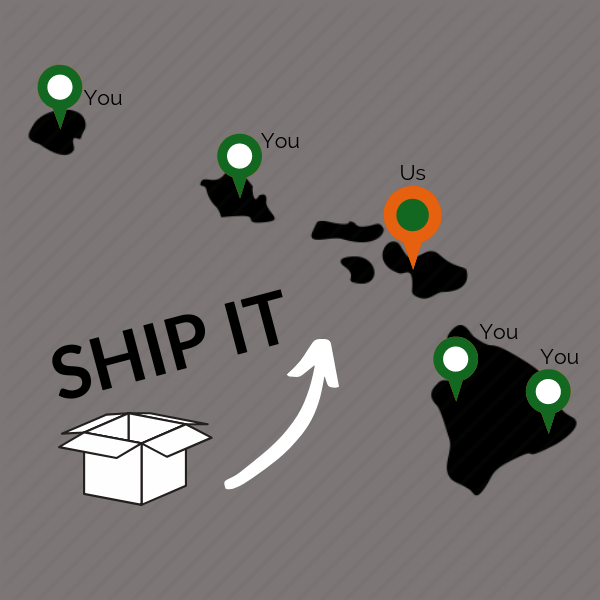

Ship Your Rims

Now serving all islands. We offer free pick up and delivery from the airport or dock with a quick turnaround. Click here for more details.

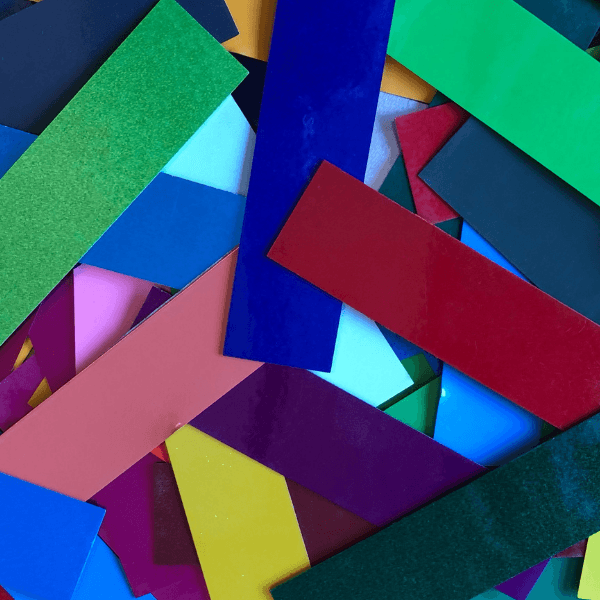

Free Colors & Samples

Come by anytime to see our samples and color charts. We have illusions, metallics and solid colors and more. We can also order any samples you want for FREE. View what others have done in the galleries.

Custom Builds

Got a show coming up? A race to compete? Call early. We’ll work with you on color, styling, and timing. Work with a SEMA Member since 2018.