Avoid Outgassing in Magnesium Wheel Restoration

How to repair old magnesium parts & avoid outgassing and corrosion

Uses of magnesium in auto parts like wheels, cylinder head covers, door panels, steering wheels, and intake manifolds have its advantages and disadvantages. It’s lightweight and easy to cast. And especially useful when weight or balance issues become apparent in high-performance vehicle production. The downside is that it is subject to easy corrosion compared to other metals.

Today’s OEM & Magnesium Parts

Over the years the cost to produce magnesium parts has been more expensive allowing aluminum and aluminum alloys to become more mainstream. But a new extrusion process could change all this, making it optimal for production in the broader market and lower costs.

Today’s mag wheels are alloys which means they are made from a composite of metals to increase strength and lower corrosion. They can even include materials such as carbon fiber rims an upgrade to the popular 2022 BMW S100RR. In that case, you may want to go straight to painting and avoid powder coating because the heat may weaken the type of composite alloy.

Outgassing When Restoring Old Magnesium

As the saying goes: “ if you have it… you might as well use it.”

In this case, restore it.

For vintage car wheels & parts, restoration is possible. Owners & restorers need to be keen on potential drawbacks and options for finishing old magnesium.

There are a couple of different approaches to how we restore magnesium wheels in powder coating. It starts at the primer base which I will address in a moment.

Old School Mags in RAL 7015 Slate Grey

Primers are fundamental

This next step is really important.

Start by pre-heating the part to peak temp for powder coating. For us, that’s @380 degrees. This part of the process helps minimize(or rather encourage) out-gassing which will most certainly occur with magnesium part restoration.

Finish it right

OGF primers are good primers but can be difficult to sand because its function is to eliminate the extra work of having to sand in between coats caused by outgassing or bubbling in the first place. When it comes to magnesium though there is no way to avoid this.

Now, be sure they coat it hot when applying the primer. It will start to flash off(cure) while applying at this stage. Depending on their skill level or aptitude they can either do a full cure or partial cure.

Again when it comes out it will have some bubbling even with OGF primer. From there they can sand it and then finish with your color choice.

Alternative Approaches

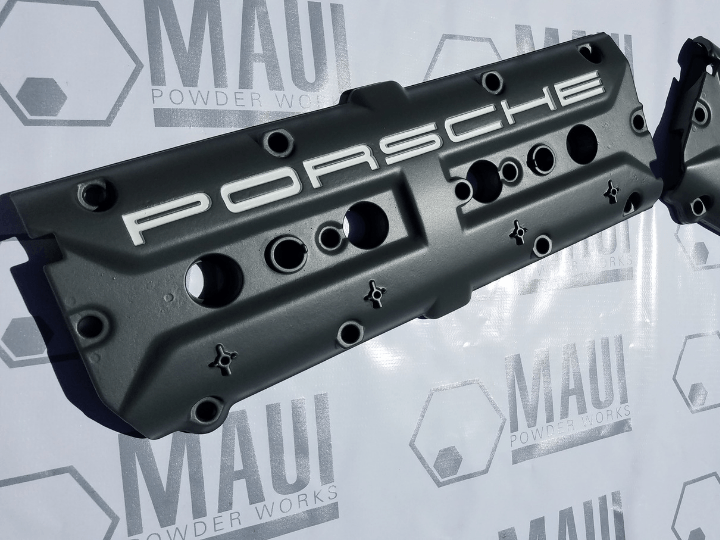

There is an alternative to the process if you like or if your coater is still unsure. Instead of priming, we went right to powder coating on a magnesium Porsche valve cover. For that piece, we color coated twice, sanding in-between coats, and finished with a matte clear. This worked well for the surface build-up and minimizing the bubbles. It also kept mil thickness within reasonable levels.

Porsche valve covers coated in RAL 7015 Slate Grey with matte clear coat

Key takeaways:

Remember magnesium can out-gas like crazy so please go into the project thinking worst-case scenario. The outcome of your magnesium part will depend on the skill level and patience of the coater. Find one that gives attention to detail even if you have to pay a little more. Also, be understanding that this is not a common metal and most coaters may not have ever dealt with it. Finally, as the car part-owner be understanding that there may be some flaws in its surface even after the restoration process. Most top-level bespoke coaters are perfectionists at heart and they want to give you the best in service as much as they can.

About us

RossKote is committed to sharing their experience in metal coatings, painting, and restoration so customers & powder coaters can navigate the process of powder coating and make the best choices for getting their projects done.

RossKote regularly contributes helpful videos on his blog and YouTube channel.

Join us. As we build a powder coating community online to share our passion for performance finishes by subscribing to RossKote's Powder Coater Podcast

Connect with us. Comment below. What would you like to know more about? I love to answer everyday questions to the consumer market wants to know about powder coating.

MAUIPOWDERWORKS.COM

Copyright 2016-2022©