Powder coatings & Metal refurbishing

Consumers should know that powder coatings are set to be the fastest growth segment of the coatings world because of an increasing need to make old things look new again.

Powder coatings have been around since the 1950s with the rise of essential industrial coatings. It wasn’t till the 1980s that the everyday consumer caught on to the trend of coating for their own metal refurbishing projects. Today, Powder coaters both large and small offer the world with durable coatings.

Beyond its durability however, there are other various features that have the potential to attract consumers. Namely, it’s safer and more sustainable for clients, applicators and the environment.

Antique metal restoration and classic auto refurbishing can be a valuable local resource in the circular economy. Now more clients have access to getting the things they love restored locally, all around the world!

Smaller custom powder coating shops are better for restoration

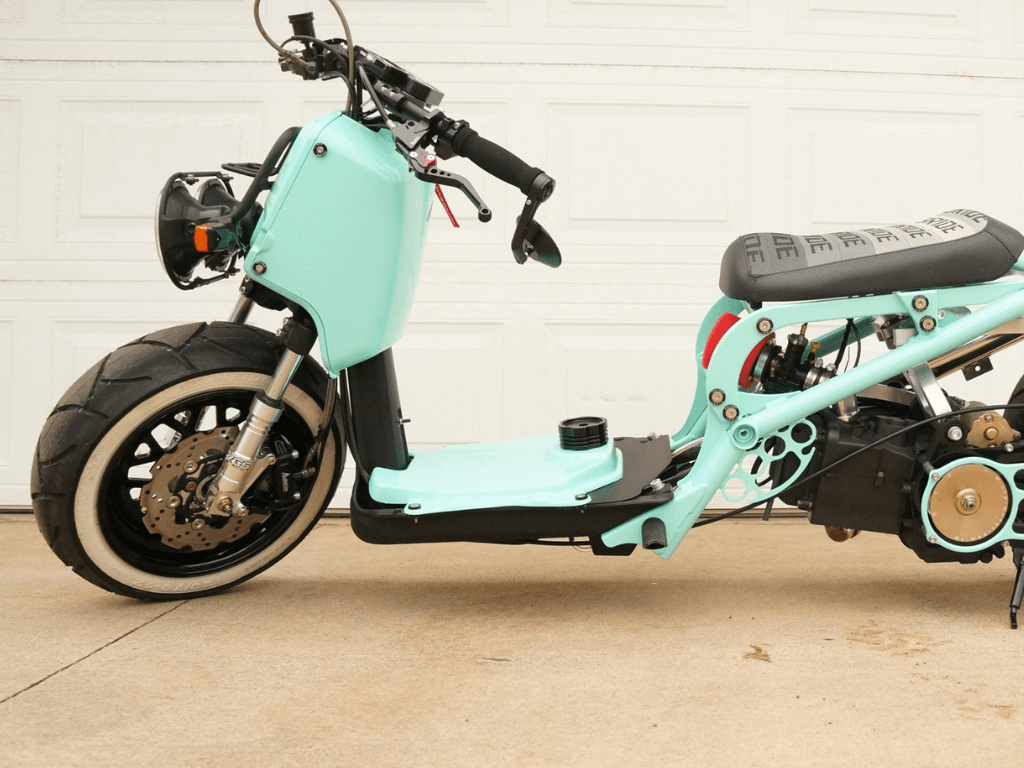

That being said it’s no wonder custom coaters grew tremendously during 2020-2021, at the height of the pandemic. Staying at home allowed homeowners, automotive enthusiasts and DIYers to get projects they’d been putting off, completed. People shopped closer to home, to help support local services resulting in the growth of metal restoration, particularly the automotive refinishing market. Local coaters are doing considerably better; they’re not experiencing too much of a slow down despite the setbacks of Covid.

So why aren’t powder coatings used more everyday? To answer this question we need to address the larger paint coatings market.

Kevin Coursin, Executive Director of the PCI has been in the paint industry for over 40 years, says powder coatings are about 6% of the global coatings market. So it is still a growing market.

In North America alone there are about 6,000 powder coaters, both big and small using about 181 Kilo tons of powder or $1.3B annually. That’s small when compared to the 27.3B liquid paints that need harmful additives to keep viscosity before applying.

Big conveyor line powder coaters are harder to access for the individual restoration market, because they strictly work based on contract. The everyday consumer doesn’t need that level of service. Most custom coaters have the flexibility and adaptability to handle variable sized jobs, because they use a batch oven – think of an oversized kitchen oven.

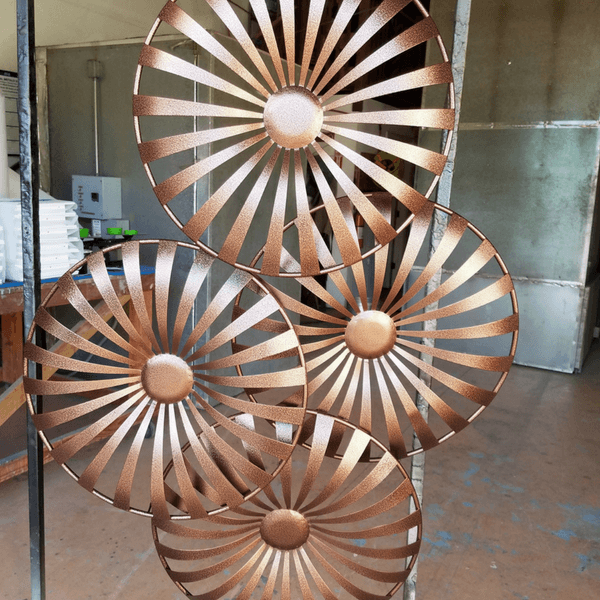

Compared to other coatings, batch coaters in particular have been growing more and more each year. From your neighborhood garage coater to the workshop professional, the message about the process of powder coating is getting out. The peace of mind that clients have about a better coating that is healthier for home, work and play is priceless.

Why Powder Coatings Are Safer

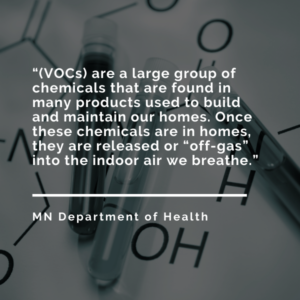

Andrew Pace, of The Green Design Center, has been consulting homeowners since the 90’s. Offering resources on healthier options for their home design needs. His clients are people with serious chemical sensitivities; or aware of the health hazards and pollutants found in homes, especially volatile organic compounds (VOCs).

He’s been recommending powder coated materials because they are VOC free, and thus reducing the overall chemical load in the homes of consumers. Andrew says “[for] the powder coatings industry, the fact that it’s going on dry. And it’s been baked in. Means that there are no volatile (organic compounds). Because there’s no solvent to evaporate. So the product is naturally VOC free. The product is by design VOC free.”

It’s no question that the health and safety of the end user is factored in for custom coaters. And for the long term enjoyment and use, it is also beneficial for the pockets of clients.

Is Metal Restoration Worth It?

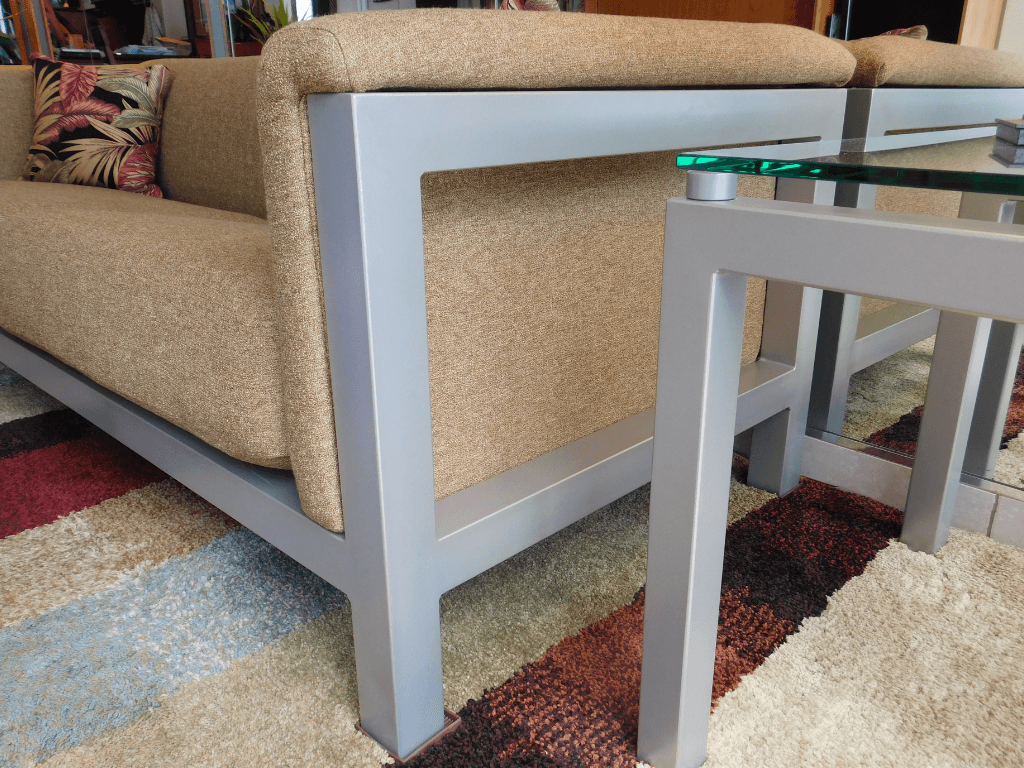

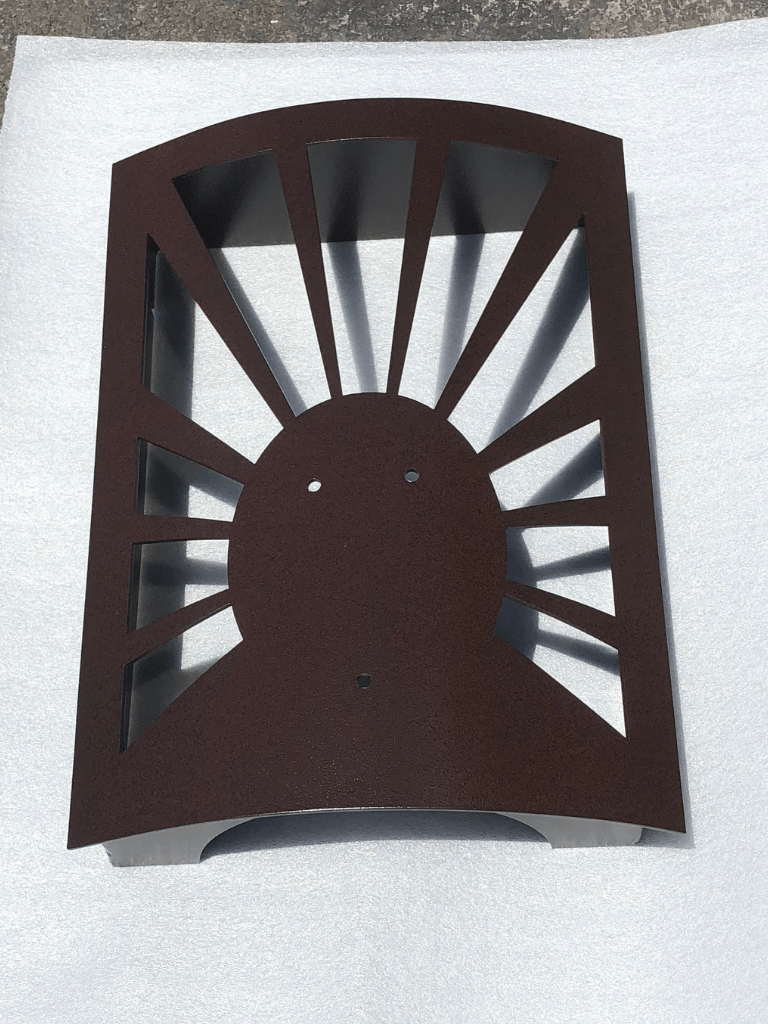

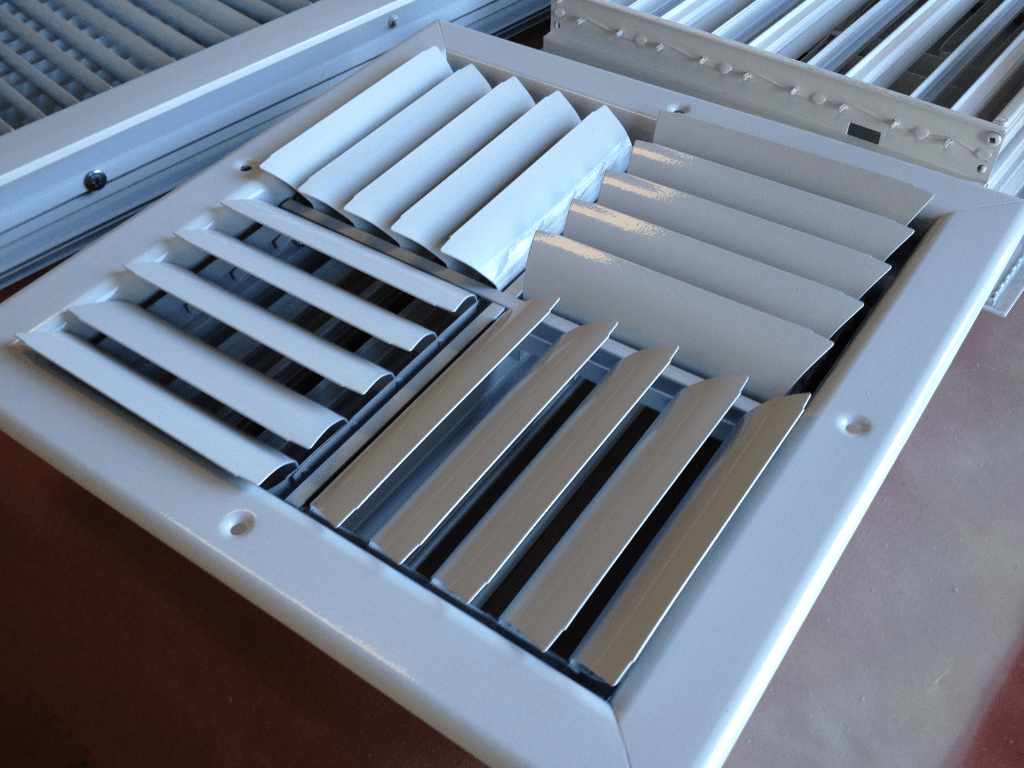

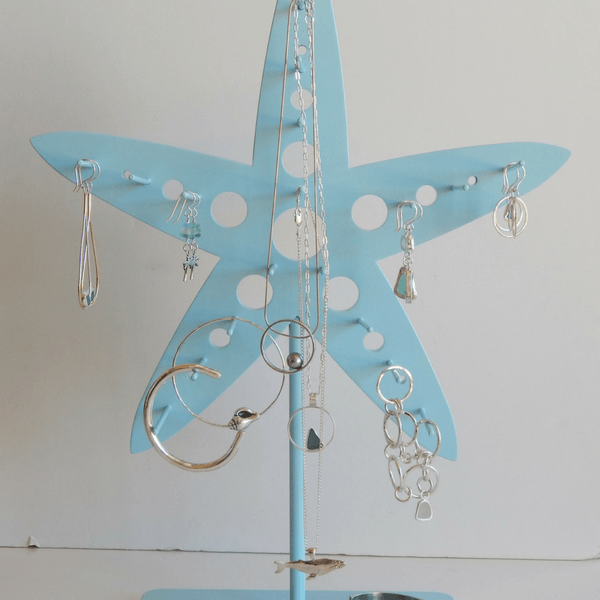

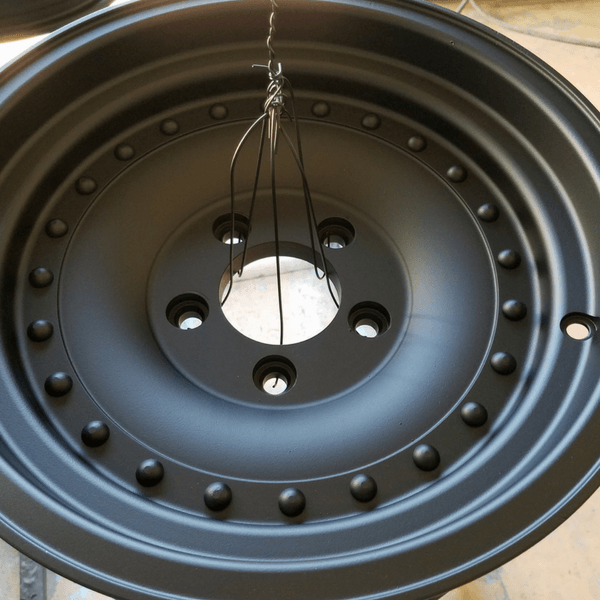

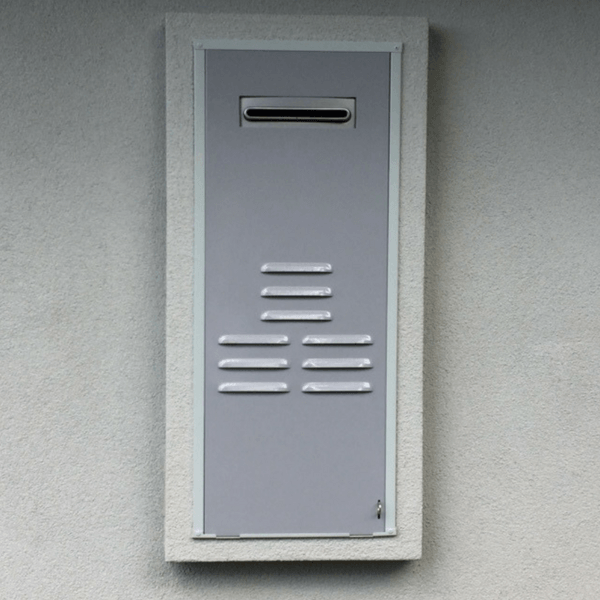

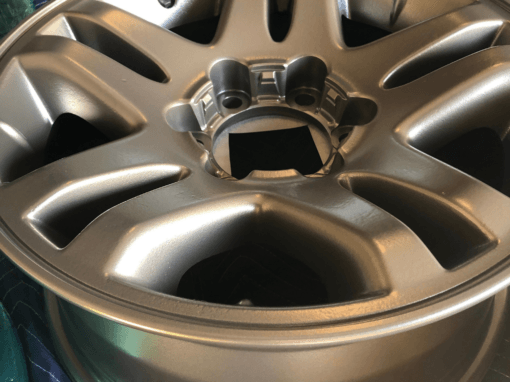

There’s nothing greater than the satisfaction of refurbishing a treasured metal antique or automotive part. When applied, powder coating is more even, and less likely to drip than liquid coatings. Powder coating withstands cracking, fading, peeling, chipping and is chemical resistant.

It doesn’t need maintenance, regular upkeep or re-coating over time. While painting requires longer cure times and fume ventilation; powder can be applied quickly and easily electrostatically, then heated till cured. Once the item is cooled they are ready to be put into service immediately. Powders adhere precisely without waste, unlike paints, so there is no need for a lot of over spray.

When a custom coater does a beautiful antique metal restoration job, it can renew the life of a priceless family treasure for a lifetime. The bottom line, it’s simply worth the money when it comes to things that hold intrinsic value or special memories of its owner. That being said, it’s important for consumers to keep in mind price variants. This is either due to location, cost of doing business and/or price increase from ongoing global supply chain disruptions. Thankfully finding a custom coater has never been easier before with the access of the internet at the clients fingertips.

How to Find Metal Restoration Near Me?

With a simple search and click of a button consumers can effortlessly find powder coaters readily available. A great search directory to use is www.powdercoatingnearme.com.

A list of qualified coaters will be brought up instantaneously.

Consumers can look up shops in their local area and gain buyer confidence with verified listings. They can view photos of a coater’s work and connect instantly with their social media accounts, view maps with shop location, hours and contact information.

Once on the site, simply scroll down to the map, where you can enter your town, city, state and/or zip code. A list of qualified coaters will be brought up instantaneously. Or maybe you’re looking for a powder coater that knows how to refurbish metal for a particular project like rims, brake calipers etc. Continue to scroll down on the main page where you can find custom coaters based on category.

For example, you need to find a coater that knows how to restore tools for metal restoration in agricultural, architectural or marine sectors. This growing database is easy to use and filled with verified custom coaters.

Key Takeaways

So there you have it, as a consumer reading this article, you should have a basic understanding of why powder coatings are important to refurbishing metal furniture, car rims or grandma’s favorite antique. In conclusion powder coating is durable, long lasting, safe and green for your wallet and the planet. It’s a growing market and not everyone is aware of the potential that custom coaters can offer no matter the size of the project.

Finding a custom coater in your local area has never been easier with www.powdercoatingnearme.com

Consumers will be surprised by the knowledge experienced custom coaters have in restoration of metal things. Always ask your powder coater questions, if you want to avoid problems with your custom coater Lastly, not everything can be restored well, understanding the restoration process of something old is complicated, and is key to spending your money wisely .

About us

RossKote is committed to sharing their experience in metal coatings, painting, and restoration so customers & powder coaters can navigate the process of powder coating and make the best choices for getting their projects done.

RossKote regularly contributes helpful videos on his blog and YouTube channel.

Join us. As we build a powder coating community online to share our passion for performance finishes by subscribing to RossKote's Powder Coater Podcast

Connect with us. Comment below. What would you like to know more about? I love to answer everyday questions to the consumer market wants to know about powder coating.

MAUIPOWDERWORKS.COM

Copyright 2016-2022©